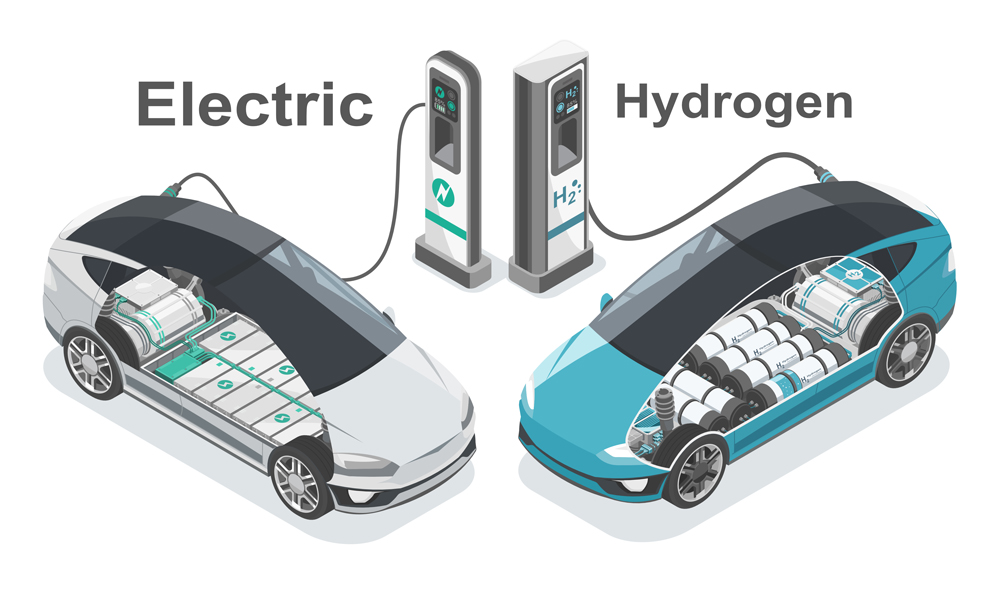

Hydrogen cars, also known as Fuel Cell Electric Vehicles (FCEVs), use hydrogen gas to generate electricity to power an electric motor. The hydrogen gas is stored in high-pressure tanks, and when it is needed, it is passed through a fuel cell stack, where it reacts with oxygen from the air to produce electricity. The electricity then powers an electric motor to propel the vehicle, emitting only water vapor as a by-product.

India has shown interest in developing a hydrogen fuel cell ecosystem as a part of its plan to reduce greenhouse gas emissions and promote clean energy. The Indian government is exploring the use of hydrogen fuel cell technology in public transportation, such as buses and trains, and is also working on a pilot project for hydrogen-powered vehicles.

Hydrogen cars have several advantages over other types of electric vehicles. First, they offer a longer driving range than Battery Electric Vehicles (BEVs), which need to be charged frequently. Hydrogen fuel cell vehicles have a driving range similar to traditional gasoline-powered cars, making them a more convenient option for long-distance travel. Additionally, hydrogen fuelling stations can refuel a car in just a few minutes, compared to the hours it takes to charge a BEV. Hydrogen cars, powered by Green Hydrogen, also produce zero emissions, making them an attractive option for those concerned about air pollution and climate change.

As is well known, Hydrogen is considered “Green” and therefore a “clean” fuel only when it is produced using renewable energy in a process called electrolysis, which involves channelising an electric current through water. The energy from this current breaks the bonds in the water molecules, releasing separate hydrogen and oxygen atoms. And because the electricity used in this process is generated from a renewable power source such as a solar array or wind turbine, no climate pollution is released. This gives rise to the term “Green Hydrogen”. It must be kept in mind that availability of commercially operable electrolysis technologies is still a concern since the technology is still at a nascent stage, and therefore one must be wary of the use of “Dirty” Hydrogen. “Dirty” Hydrogen (or “Grey” or “Blue” Hydrogen) is generated using Coal, Gas or Steam Methane.

Hydrogen fuel cell vehicles are currently more expensive than other types of electric vehicles, such as BEVs and Plug-in Hybrid Electric Vehicles (PHEVs).

Production Cost:

BEVs: The production cost of BEVs in India can range from approximately Rs. 7 lakh for a hatchback to Rs. 35 lakh for a premium SUV. In BEVs, the battery is typically the most expensive component. The cost of batteries has been decreasing over time due to advancements in technology and economies of scale, but it still accounts for a significant portion of the total cost of the vehicle.

BEVs: The production cost of BEVs in India can range from approximately Rs. 7 lakh for a hatchback to Rs. 35 lakh for a premium SUV. In BEVs, the battery is typically the most expensive component. The cost of batteries has been decreasing over time due to advancements in technology and economies of scale, but it still accounts for a significant portion of the total cost of the vehicle.- PHEVs: The production cost of PHEVs in India can range from approximately Rs. 18 lakh for a mid-size sedan to Rs. 90 lakh for a luxury SUV. PHEVs have a smaller battery than BEVs, but can run on both electric and petrol.

- FCEVs: The production cost of FCEVs in India is currently higher compared to BEVs and PHEVs due to the high cost of fuel cell technology. It can range from approximately Rs. 1.2 crore for a sedan to Rs. 1.8 crore for a premium SUV. For FCEVs, the most expensive part is the fuel cell stack, which is responsible for converting hydrogen into electricity to power the vehicle’s motor. However, the cost of fuel cell technology has been decreasing over time as well, and there are ongoing efforts to further reduce costs. Regarding charging costs, it can vary depending on factors such as the price of electricity, the efficiency of the vehicle, and the type of charging station used. In general, BEVs and PHEVs are cheaper to charge per kilometer than FCEVs and petrol vehicles.

Charging Cost:

| Vehicle Type | Charging / Fueling Cost (per unit) | Cost per km | Range | Notes |

| FCEVs | Rs. 450-550 per kg of hydrogen | Rs. 4-5 (Rs. 450 / 112.5 km) |

400-500 km per full tank (5kg capacity – 112.5 km per Kg travelling) |

Easy to refuel like Petrol |

| BEVs | Rs. 5 – 8 per kWh | Rs. <1-2 (40 kWh * Rs. 5) / 350 km = <1 |

350-400 Km Per full tank (40 – 100 KWh) majority is 40 KWh |

Charging speed depends on car model and electricity rates based on the region |

| PHEVs | Rs. 5-8 per kWh for charging and Rs. 95-105 per liter | Rs. <1-2 in electric mode and Rs. 4-7 in hybrid mode | 500–1200 km full tank (12 – 16 KWh) majority is 14 KWh And 15-30 km per liter (in hybrid mode) with 40 litre capacity |

Can run on both electric and petrol, smaller battery than BEVs |

| Fuel Vehicles | Rs. 95-105 per liter | Rs. 7-9 (Rs. 95 / 12 km) |

540–900 km full tank (12-15 km per liter) with 40 litre capacity |

Highly fluctuating rates but easy to refuel |

Maintenance and Repair Cost:

BEVs: The maintenance and repair cost of BEVs in India is generally lower compared to conventional gasoline vehicles since they have fewer moving parts and require less frequent oil changes and other routine maintenance. However, the cost of replacing the battery can be significant, depending on the model and manufacturer. For example, the cost of replacing the battery of a Tata Nexon EV with a 30.2 kWh battery can be around Rs. 2 lakhs to Rs 2.5 lakhs.

BEVs: The maintenance and repair cost of BEVs in India is generally lower compared to conventional gasoline vehicles since they have fewer moving parts and require less frequent oil changes and other routine maintenance. However, the cost of replacing the battery can be significant, depending on the model and manufacturer. For example, the cost of replacing the battery of a Tata Nexon EV with a 30.2 kWh battery can be around Rs. 2 lakhs to Rs 2.5 lakhs.- PHEVs: The maintenance and repair cost of PHEVs in India is similar to BEVs, with the added cost of maintaining the gasoline engine and the hybrid system. However, the battery replacement cost is lower compared to BEVs, since PHEVs have a smaller battery. For example, the cost of replacing the battery of a Toyota Prius Prime with a 8.8 kWh battery can be around Rs. 40,000 to Rs. 80,000.

- FCEVs: The maintenance and repair cost of FCEVs in India is higher compared to BEVs and PHEVs due to the complex fuel cell system and the limited availability of trained technicians. The cost of replacing the fuel cell stack can be significant, depending on the model and manufacturer. For example, the cost of replacing the fuel cell stack of a Toyota Mirai can be around Rs. 8 lakhs to Rs. 10 lakhs.

To conclude, whilst Hydrogen fuelled cars appear to be the future of the automobile industry, we still have a long way to go in stabilising the Electrolysis process and also making it commercially viable to own and operate an FCEV automobile. A lot of countries around the world are investing billions of dollars in this industry and we should be able to see some rapid progress in the near future.